Magnesium oxide board also named MgO board/magnesium board, is ideal solution for the construction of fire-rated floors, walls, roofs and general construction purposes. By combining the properties of magnesium oxide cement (chloride-free), with the strength of heavy duty alkaline resistant fiberglass mesh, the MgO board is suited for application where noncomputability, strength, weight, stability and cost are a concern.

Mgo board is:

• Fire resistant (Class A1) building material

• Lighter, more flexible and stable than traditional sheeting systems

• Time and material saving - dramatically reducing construction costs

• Environmentally friendly, applying a sustainable production processwithreduced CO2 footprint

• Ideal for time, safety and health sensitive construction applications

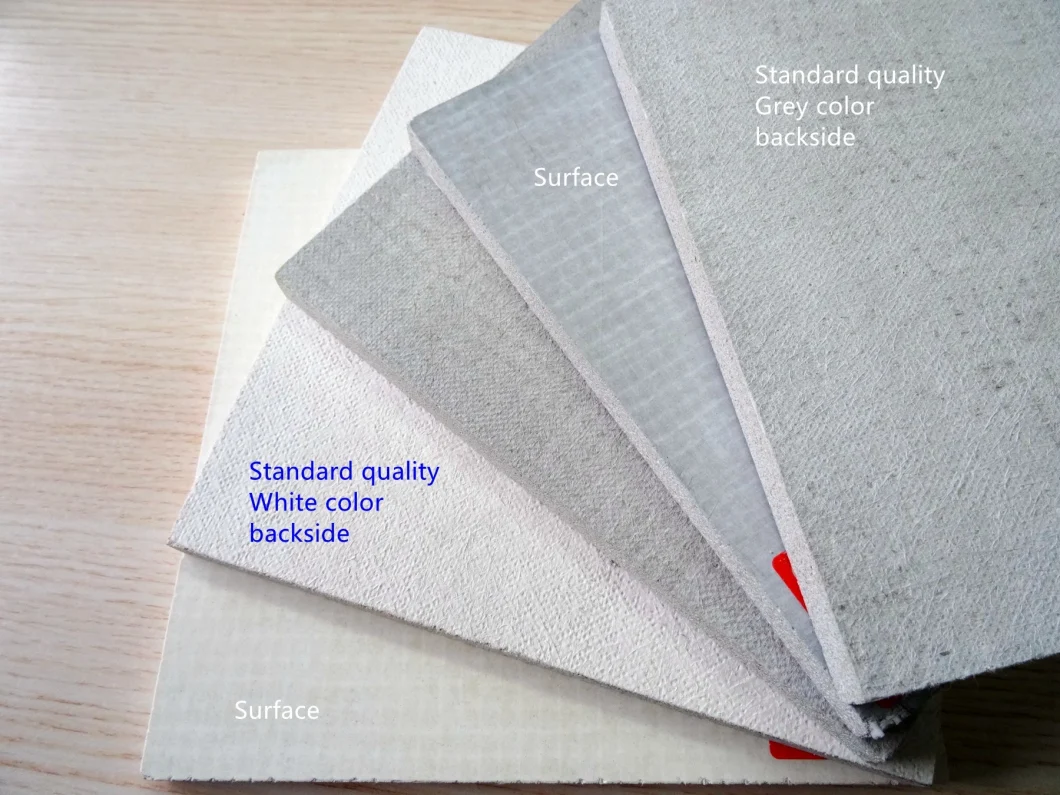

2.Colors: White, Grey, Blue, Red, Green, Yellow are availble. Also we can do other color according your request.

We use ferric oxide to produce different color, cost is higher, but the color very evenly.

3.Specification

| Specification | |

| Width: | 600/900/1200/1220, and special width |

| Length: | Standard is 2400-3050mm, special size should speically design |

| Thickness: | 3-25mm |

| Color: | White; Pink; Purple; Green; Grey; Blue; Black; Brown, etc, we can customize for you |

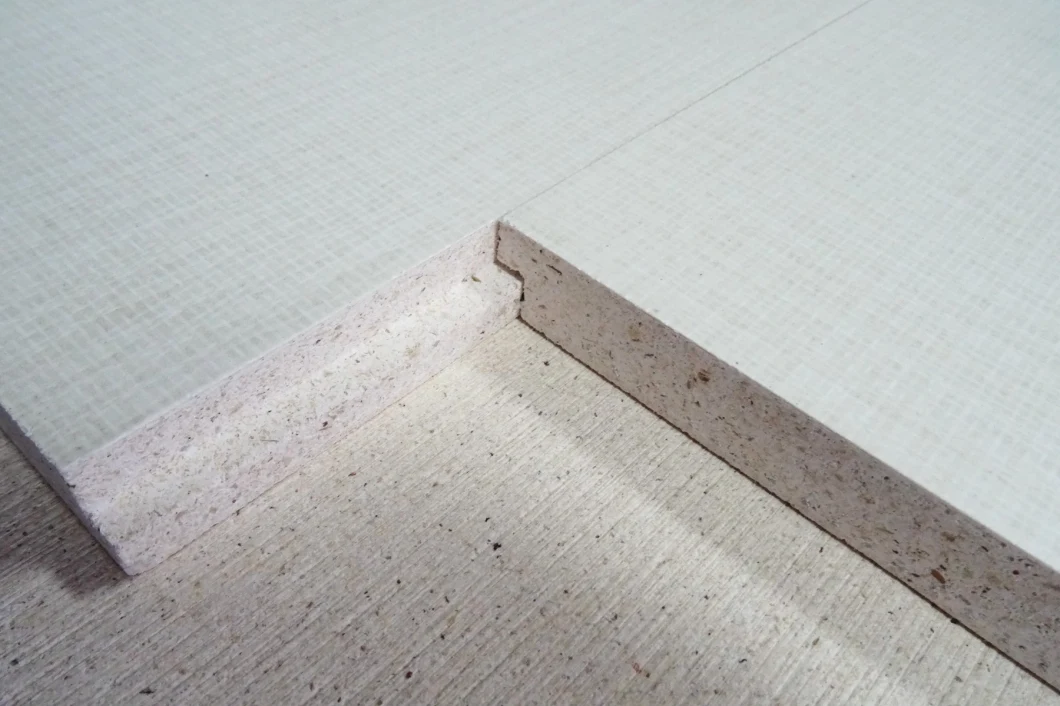

| Edge: | Square; tapered ; T&G; L - shiplap |

| Type-1 | Sanding mgo board; non-woven mgo board; HPL laminated mgo board ; Melamine paper laminated mgo board |

| Capacity | 2400 pieces/day |

4.Our advantages

1. Professional export team: full of experience to handle the export, transportation, files, and documents.

2. Experienced engineer and workers for production: Our general engineer has over 18years experience in MGO board field, proficient in the process from No.1 generation MGO board production until the newest MGO board machine design/manufacturing.

3. Strict production procedures and automatic machine to ensure the quality of our products.

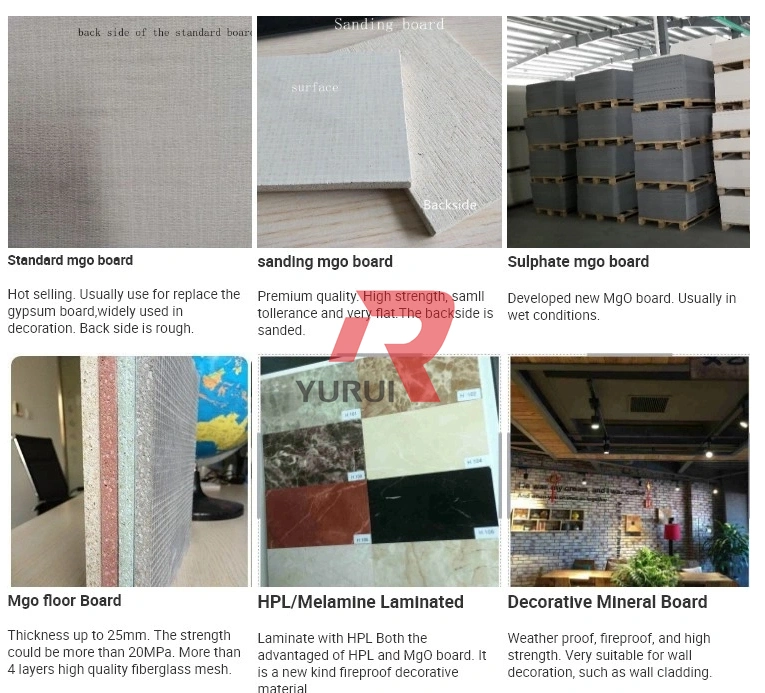

5.Different Types MgO Boards

Now in our factory, we produce mainly four different kinds of MgO board. (All based on the chloride free formula)

MGO board mainly used for interior wall, exterior wall, make SIP, Floor, Ceilings, and decoration mgo boards.

Also can used to produce fireproof door, container house, and furniture to against termites.

You can tell us your application, we will help you choose suitable mgo boards.

If you have new idea, also we can discuss to develop new products for you.

We focus on Chloride free mgo board & Customized mgo board.

Non-woven MgO Board/standard MgO board, it has a smooth surface and rough backside, generally use two layers of fiberglass mesh and two layers of Non-woven fabric. The fabric is only could make the appearance of the backside more smooth, won't benefits for the strength

Sanding MgO Board. This is a premium quality MgO board, it has a very smooth surface and sanded backside. Because the production process isdifference from the common MgO board, the price is higher than the common MgO board. Its backside has been sanded, so the thickness tolerance is very small.

Floor MgO board. This kind MgO board is specially designed for the projects need high strength performance. For examples, floorings. To this board, we will use high standard mesh (up to 300g and special quality) This kind of mesh is much longer working life and stronger than the common mesh.

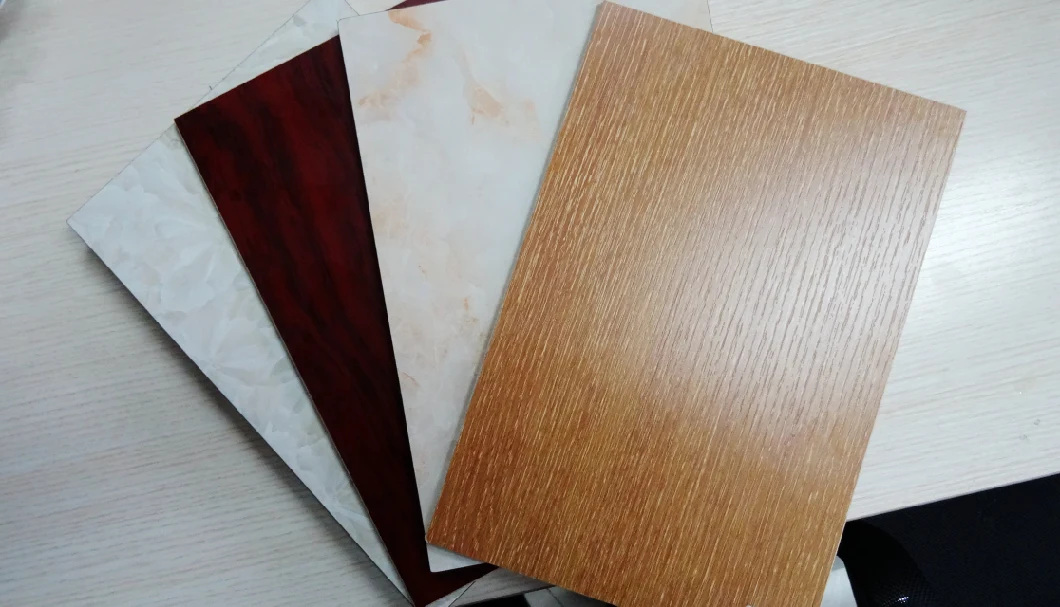

Laminated MgO board. Now in our factory, we could provide the HPL laminated MgO board and melamine paper laminated MgO board. This board combines the HPL/melamine paper on the Sanding MgO board. So, it has both advantages of the HPL/Melamine and MgO board. Fireproof, high strength, waterproof and easy to clean.

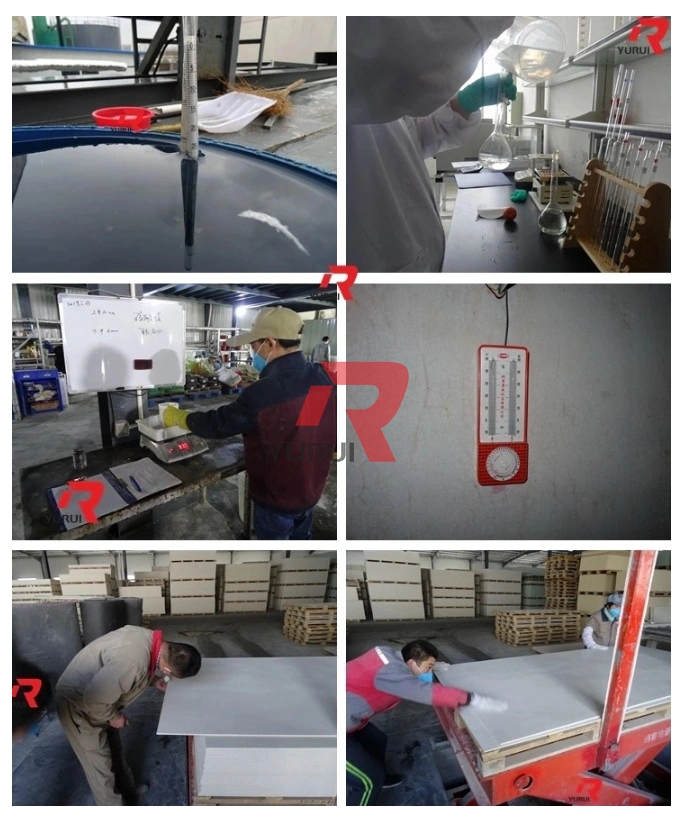

6. Our Control System.

We have whole QC system,

From raw material, material test, production line, curing room, packing, and our own lab.

All of them to guarantee our qualicyt stable.

When you visit us, you will impressive.

If you do not have time visit us, We can have a living video to show you our whole factory.

7.Packages

1) Before loading, we will screw the Green color PE strip in the pallet. This way couldguarantee the whole pallet is muchmore stronger and the pallet will not be destroyed after the long time transportation. When customer do the unloading, sometimes the forkliftdestroy the PE strips. If we screw the PE strips into the wood, then this kind of problem will be avoided, could grantee there is no risk when customer do the unloading.

2) If there is some space between two pallets, we will useDunnage bag.

3) Strong wood pallets

4) Corner Protection & film loading is the final step for the manufacturer, we need to 100% make sure it is safe after the long-distance transportation.

8. FAQ

Q1. How do you pack your boards?

A: Generally, we pack our goods in strong wood pallets.

Q2. What are your terms of payment?

A: T/T 30% as deposit, and 70% against to the BL copy.

Q3. What are your terms of delivery?

A: FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples. If you have special requirements of the products, we also could discuss with our engineers.

Q6. Could you provide samples?

A: Sure, please contact us now.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

If you want know more information about MGO board, Pls kindly send me an Inquiry

↓↓↓↓↓