Magnesium oxide board also named MgO board/magnesium cement board, is ideal solution for the construction of fire-rated floors, walls, roofs and general construction purposes. By combining the properties of magnesium oxide cement (chloride-free), with the strength of heavy duty alkaline resistant fiberglass mesh, the MgO board is suited for application where noncomputability, strength, weight, stability and cost are a concern.

Chloride-free MgO Board/ sulfate mgo board / MgSO4 Boardis also named as Magnesium Sulfate MgO Board, is a kind of new fireproof board which widely be used in construction and decoration. It is a new type non-flammable material made of lightweight materials.

The MgO Sulfate board is made from magnesium oxide, magnesium sulfate, Wood fiber, Perlite, fiberglass mesh. The highly purified MgO is used as the main fireproof material, wood fiber and perlite are used as filling materials. Without chloride ions, solve the problems of light corrosion and moisture absorption.

Features

2. Waterproof, Anti-halogenation,moisture-proof, anti-corrosion, acid and alkali resistance.

3. Heat insulation,sound insulation.

4. Low stretching rate,light weight and high strength,overall low density.

5. Smooth surface, can be painted,, paste tile, paste wallpaper and otherdecorative materials.

6. Good fire resistance performance,12mm thickness plate can be made partition, it can reach 4 hours fire resistance.

7 .Construction of low wear and tear, can be cut,saw,nail,bent.

8.Free from smog, poison,smell , erosion,crack , distortion

9.Good safety performance: This product is 100% free of asbestos and radiation, it will not create the organic substance harmful to human bodies.

Specification | |

Width: | 600/900/1200/1220, and special width |

Length: | Standard is 2400-3050mm, special size should speically design |

Thickness: | 3-25mm |

Color: | White; Pink; Purple; Green; Grey; Blue; Black; Brown, etc, we can customize for you |

Edge: | Square; tapered ; T&G; L - shiplap |

Type-1 | Sanding mgo board; non-woven mgo board; HPL laminated mgo board ; Melamine paper laminated mgo board |

Capacity | 2400 pieces/day |

INTERNAL APPLICATIONS

Wall Board / Backing Board / Ceiling / Flooring

Acoustic Protection / Kitchen Furniture / Wet (Bathrooms, Kitchens, Basements)

EXTERNAL APPLICATIONS

External / Cladding / Racking / Forming / Shuttering

Sound Barrier / Construction Sites / Advertising / Hoarding

Complete External Wall Systems

OTHER APPLICATIONS

Aviation / Pallets / Lining / Maritime

Frames and Partitioning / Oil & Gas / Security and Defence

PACKAGE AND DELIVERY

All the package could be customized by customers, such as the packing material, quantity per pallet, we could discuss to get a best solution for both of us.

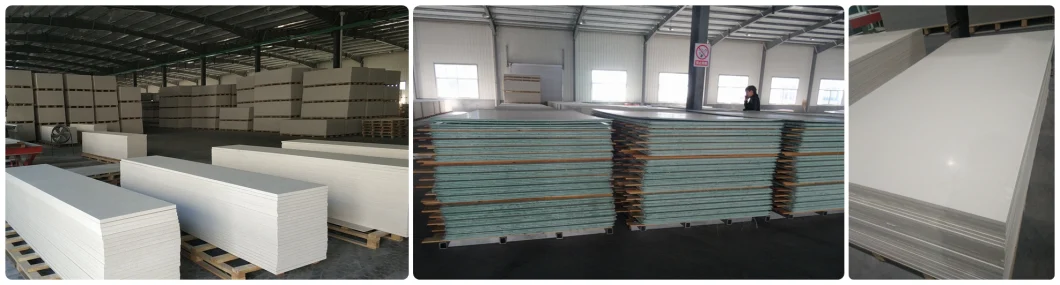

OUR FACTORY

Shandong Yurui Construction Materials Co., Ltd mainly produces MgO Board. Main products are Common MgO board and Sanding MgO board. We have the latest generation automatic production equipment and professional technology of pure sulfate recipe. Our products have been exported to the USA, Canada, Australia, Southeast Asia, Africa, and South America, Middle East countries and some other countries. We aim to gain the market and customers from high-quality products and good reputation.

Our advantages

Q | What is the production capacity? |

A | 2000 sheets per day |

Q | What is the delivery time? |

A | Generally is 15-20 working days after received 30% deposit. |

Q | Can we mix different thickness and different color into one container? |

A | Yes no problem, we could calculate the loading quantity and solution for you. |

Q | What is the payment terms? |

A | Generally, TT. 30% as advance, the balance 70% before loading. |

Q | How do you guarantee your quality? |

A | We have a very strict quality control system in our factory. Every production process part has relative records about date and time. We have very a very detailed quality control document, if you need, I can show you. |

Q | How to guarantee the package no break after long-distance transportation? |

A | We use strong wood pallets, the base tray of the pallets is 13mm fumigated wood. If the package break because of the pallets, we will take full responsibility. |

Q | How could we know that you can supply real good quality MGO board as you said? |

A | We understand your worries. We could do business through Alibaba Trade Assurance, if you are not satisfied with the MGO board's quality, it will do the compensation for you. Here is a link for your reference: http://yurui2018.en.made-in-china.com |